The AirCal 1000 delivers a controlled concentration of calibration gas for calibration of ambient gas monitors. To do this, the calibration gas inside the cylinder is mixed with zero air, which is generated by the scrubbing material inside the AirCal 1000.

The calibration gas is therefore diluted by the zero air to provide a given concentration which is directed into the monitor. The concentration of calibration gas is calculated using a dilution ratio which is determined by the zero air and cylinder gas flow rates.

- The zero air generator delivers a flow rate of approximately 2–2.5 LPM. The flow rate of the zero air is monitored using a mass flow meter (MFM).

- The flow rate of the cylinder gas is controlled dynamically using a mass flow controller (MFC). The cylinder gas flow rate can range between 5–45 ml/min-1.

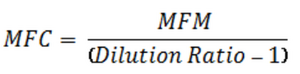

The MFC adjusts the flow of the calibration gas to maintain a user-defined dilution ratio according the equation:

The user-dilution ratio needs to be calculated in order to deliver the required concentration of calibration gas.

Example: If 10ppm of CO is required and the cylinder concentration is 1000ppm, the required dilution ratio would be 100. The dilution ratio of 100 is entered into the relevant section, either in the PC software or manually on the instrument screen and the MFC flow rate automatically adjusts to meet the desired calibration gas concentration.