Introduction

Aeroqual provides a series of monitors, including hand-held monitors and fixed monitors that pair with our gas-specific sensor heads. This pairing can be used for a range of applications in indoor air quality, environmental monitoring, and industrial health and safety. To help you get the most out of your device, we have compiled some information on how we at Aeroqual test the sensor heads prior to shipping them to customers. Carrying out a similar style of testing before deploying your sensor head can provide increased confidence in the reliability of your device. If you are having problems with your testing results, completing these suggested tests will improve your ability to troubleshoot any issues and ensure project success.

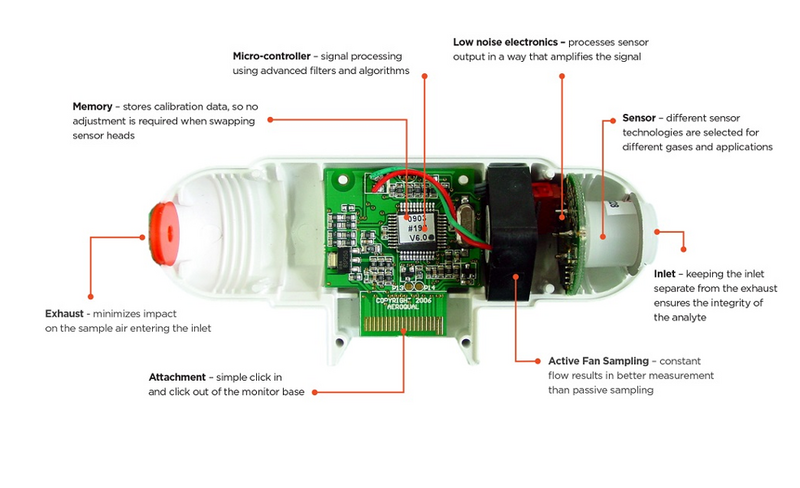

You can see the inside of a sensor head below. Each sensor head has a different sensor (either a GSE (gas sensitive electrochemical) or GSS (gas sensitive semiconducting) sensor) tuned to detect a specific target gas.

Part 1 – How we test sensor heads at Aeroqual.

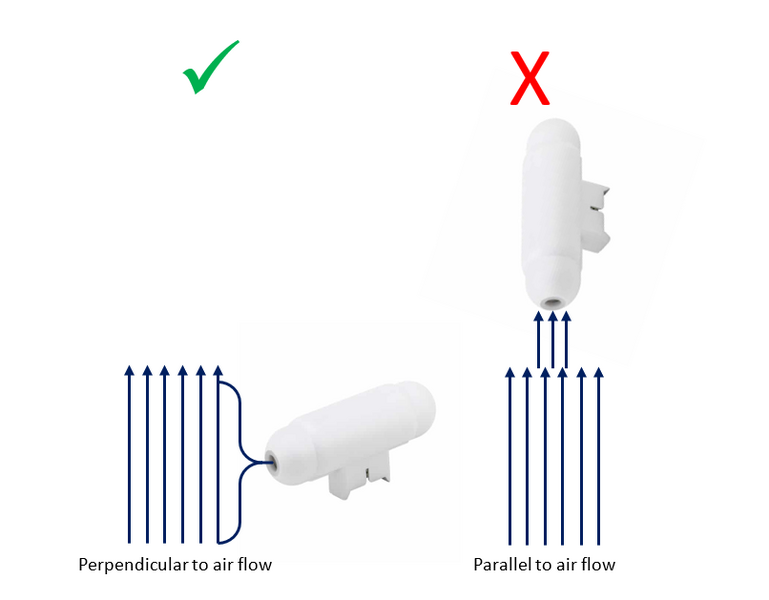

At Aeroqual, most of our sensor heads are tested in a 1 or 2 m3 sealed, rectangular chamber with internal ventilation to ensure that gas concentrations during testing are as homogenous as possible. The walls of the chambers are glass, so they do not off-gas anything that can affect the readings inside the chamber. Aeroqual sensor heads are designed to operate in ambient air. The sensor heads should not have gases pushed through them (or pressure applied that is above ambient air). The following figure shows the appropriate way to sample air when using a sensor head. If the sensor head is directly in the airflow, this will force sample air across the sensor at a different rate to the standard rate supplied by the fan. This will affect the sensor reading as the sensor is calibrated to the flow rate of the internal fan.

Once the sensor heads are put into the test chamber, they are run for an extended period so the sensor can stabilize. During stabilization, the reading on the monitor will flash. This will typically take between 5 and 7 minutes. However, if the sensor head is new or has not been used for some time, it could take a few hours to stabilize and reach a consistent zero. At Aeroqual, we leave all sensor heads overnight to get a stable reading. The GSS ozone sensor heads should be given 24 hours to warm up to remove any contamination because they are designed to measure ppb levels of ozone. Span gas in a balance of air is then added to the chamber at a known concentration. The span gas concentration should be selected based on sensor range and the expected concentration for the final application. When testing sensor heads at Aeroqual, we initially have span gas at 150% of the target span concentration for 5-10 minutes, then decrease to the target concentration for one hour. The reading on your handheld unit will increase and stabilize to read the concentration of span gas in the chamber.

Part 2 – Common Issues/FAQ

GSS vs GSE Ozone sensors

For ozone measurements, we offer two different sensors; the gas sensitive semiconductor (GSS) and the gas sensitive electrochemical (GSE). The GSS sensors give very good accuracy, sensitivity, and stability at low ozone concentrations. However, if a faster response time is needed, the GSE sensor heads should be used. The GSE sensors can also be used for a wider concentration range. The GSS ozone sensors can be affected by VOCs, while the GSE ozone sensors are cross sensitive to NO2 and Cl2. The GSE is more suitable for indoor applications, while the GSS is more suitable for outdoor applications.

| GSE | GSS | |

| Range | 0-10 ppm (OZ/OZ2) | 0-0.05 ppm (OZS/OZS2) |

| Detection limit | 0.01 ppm | 0.001 ppm |

| Resolution | 0.01 ppm | 0.001 ppm |

| Response time | 60s | 60-240s |

| Zero time | No | Yes |

| Main cross-sensitivities | NO2 and Cl2 | VOCs |

VOC sensor heads

Our VOC sensor head measures total VOC content. VOC stands for volatile organic compounds. They are emitted as gases from certain solids and liquids, including paints and solvents, cleaners and disinfectants, and aerosol sprays. Examples of VOCs are short-chain alkanes and alcohols. The sensors are calibrated at Aeroqual with isobutylene. Isobutylene is a hydrocarbon commonly used to calibrate VOC sensors (including GSS and PID sensors). This means a 1 ppm reading corresponds to 1 ppm isobutylene. If you are measuring a different hydrocarbon, the response will usually be different. For example, if the VOC sensor head with a PID sensor inside is used to measure 17 ppm of heptane, it will give a reading of 10 ppm. That’s because heptane has a response factor of 1.7. The concentration of heptane measured is 10 ppm x 1.7 = 17 ppm of heptane. The response factors provided by Aeroqual allow you to convert the ppm reading into the concentration of your target VOC. If the atmosphere contains a mixture of VOCs, then the sensor head gives you the total VOC concentration in ppm of isobutylene. It cannot be used to discriminate between different hydrocarbons, and the measurement is qualitative only.

Cross Sensitivities

Although gas sensors are designed to measure a specific gas, they may also respond to other gases in the measurement environment. This is known as cross-sensitivity. The known cross sensitivities are given on the Aeroqual webpage (Sensor heads). Sensors will give a different response for each gas they are sensitive to (intended target gas and cross-sensitivity). For example, the ozone GSE sensor is cross-sensitive to NO2 and Cl2. However, its response to these gases is not the same as its response to ozone. This means if 200 ppb of NO2 is in the air, your unit will not read 200 ppb as it is calibrated to ozone, not NO2. Cross sensitivities can be positive or negative. This means that the presence of a cross-sensitive species will increase (or decrease) the concentration reading on your unit. Gas sensors can also be sensitive to fluctuations in the environment, for example, changes in ambient temperature or humidity. To reduce this effect, for example, when moving between locations (such as going from an indoor to an outdoor location), you must wait until the reading is stable before taking a measurement.

Reactive vs non-reactive gases

Some gases are reactive or unstable, which makes it difficult to establish a steady-state concentration. Care should therefore be taken when measuring the concentration of reactive gases. Here are some examples of commonly used gases that have these properties:

1) Ozone is highly reactive and cannot be stored in a bottle, therefore an ozone generator must be used to calibrate a sensor head. Ozone will react with organic compounds and surfaces, so, once generated, the concentration may not be stable. Ozone concentration gradients are common in rooms. Concentrations may be lower near walls and surfaces or areas with low airflow. More information on ozone can be found on the Aeroqual webpage (Sensors - ozone).

2) NO2 is not as reactive as ozone and can be bottled. However, it is not stable in a gas cylinder so the concentration will change with time. It is therefore important to be mindful of the age of the gas and its expiry date.

3) Ammonia is a very reactive gas and is soluble in water. This means it will be absorbed by water films on surfaces.

Differences between alternative sensor manufacturers

A common question for users arises when comparing gas sensors from different manufacturers in the same space (also called co-location) and why they may read differently. There are several things to look out for when comparing devices.

1) Some units will be pumped, while others are fan-based, which may result in different readings.

2) Each manufacturer may use different internal averaging, which can cause differences in noise and response time.

3) They may employ different measurement technologies, which can affect the readings (see our section on GSS versus GSE sensors).

4) The accuracy, precision, range, or resolution of instruments can differ. Make sure when selecting your sensor head, you understand what you are trying to measure and what may be the expected results. For example, if you plan to measure a maximum of 100 ppb ozone, a sensor head that has a range of 0-10 ppm may not be suitable. A more appropriate range may be to try a 0-150 ppb range, so the full scale of what you are expecting fits nicely into the range of the sensor head.

AS R42 and RGR CALKIT Calibration Accessories

The AS R42 calibration accessory and the RGR CALKIT calibration accessory allow you to deliver a constant flow of gas across your sensor head without forcing gas through the sensor head. The AS R45 in particular also has the capacity to control the humidity of the gas, so can help mitigate any changes due to changes in ambient humidity and make your reading more stable. The AS R42 and RGR CALKIT are a great option to check your sensor head when you do not have access to an appropriate chamber.

Note that AS R42 can only be used for the S500 and S300 handheld monitors, while RGR CALKIT can be used across Ranger handheld monitor and S500/S300 handheld monitors.

My ozone sensor head is readings “warm-up” constantly. What should I do?

GSS ozone sensors are susceptible to contamination by VOCs. Usually, VOC concentration is higher indoors, so if your ozone sensor is reading “warm-up” constantly, trying moving it outside to see if it can warm up without the presence of VOCs. Note that this is for GSS ozone sensors, and GSE sensors are much less susceptible to VOCs.

My ozone sensor head can’t zero?

The GSS ozone sensor goes through a zero cycle to improve accuracy and improve the zero reading. The GSE ozone sensor does not go through this zero cycle and will need to be zero calibrated from time to time. This is especially true if the sensor head is not reading zero when the ozone level is <0.01 ppm. There are two options for zero calibration – to use zero air (a highly accurate approach) or a re-zero in a low ozone environment (ozone <0.01 ppm). If using zero air, follow the same approach as with span gas, having the sensor head in a chamber or using the AS R42 or RGR CALKIT calibration accessories, but using zero air rather than span gas.

GSE ozone sensors can be affected by exposure to very high levels of ozone, and the baseline can become more negative by 0.1-0.2 ppm. This means that if the ozone concentration is 0.1 ppm, the monitor may read 0 ppm. This effect can last up to 24 hours, so, following high ozone exposure, use a second ozone sensor to validate low-level measurement.

My sensor head reads “sensor failure”?

Gas sensors do have a limited lifetime and will require replacement after extended usage. We recommend you return your sensor head for factory recalibration after one year and replace it after two years. If you are using your sensor head in particularly harsh environments (for example, in hot or dry areas or areas where the humidity is high for long time periods), the sensor head may require replacement sooner. If your device reads sensor failure, the sensor head needs replacing.

Are there any sensor heads that need to be calibrated at the factory?

Ammonia, perchlorethylene and particulate sensor heads can’t be span calibrated in the field. These must be factory calibrated.

Conclusion

There are many factors to consider when choosing a sensor for your gas measurement application. Having a plan on what you want to measure, how, and the best technology to make the most of your project is key. If you require further assistance with selecting the right sensor head for your application, please contact our Sales team, or visit our Support Center.

Support Center:

Sales: