Introduction

Use the procedure to ensure your monitor is fit for calibration. It involves checking key operating parameters such as flow rates and changing the gas inlet filter.

Tools

-

-

Download the calibration results form at the end of this user guide.

-

Fill in tables 1, 2 and 3.

-

These tables record basic details like date and time, site name, engineer's name, and the equipment that will be used during the calibration.

-

-

-

When arriving onsite, it's important to make sure no new emission sources or obstructions have appeared since the last visit.

-

Inspect the local surroundings and check for local point source emissions such as open fires or exhaust emissions from a newly positioned generator.

-

Check for obstructions which may affect the measurements, such as a new fence.

-

Record your observations in table 4 of the calibration form.

-

-

-

Because the AirCal 1000 and Ozone Calibration Source take at least 30 minutes to warm up and become stable, now is a good time to turn both on.

-

Turn on the AirCal 1000 calibrator and switch on the pump override switch on the back panel.

-

If you're calibrating ozone, turn on your Ozone Calibration Source and set it to deliver 0.1 ppm ozone. This allows time for the lamp to stabilize at 0.1 ppm.

-

-

-

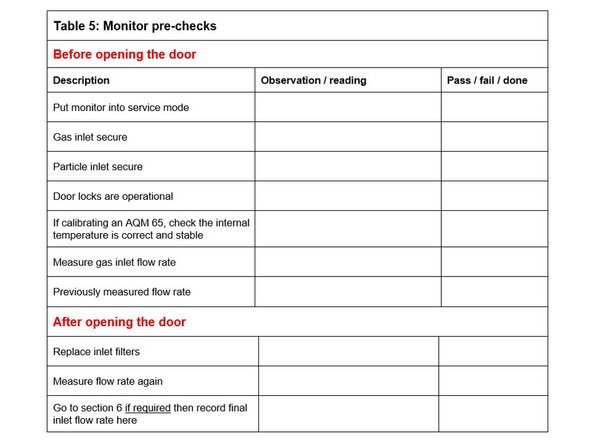

Fill in table 5 by completing the steps 2,3 and 4 in this user guide.

-

-

Check the gas inlet is secure.

-

Check the particle inlet is secure.

-

Check the door locks are operational.

-

-

-

This step only applies to AQM 65 monitors.

-

If calibrating an AQM 65, check the internal temperature has been stable at the correct temperature.

-

If the internal temperature isn’t correct, you must address this before attempting a calibration.

-

-

-

-

Record the previously measured flow rate. (You should find this in the monitor's journal.)

-

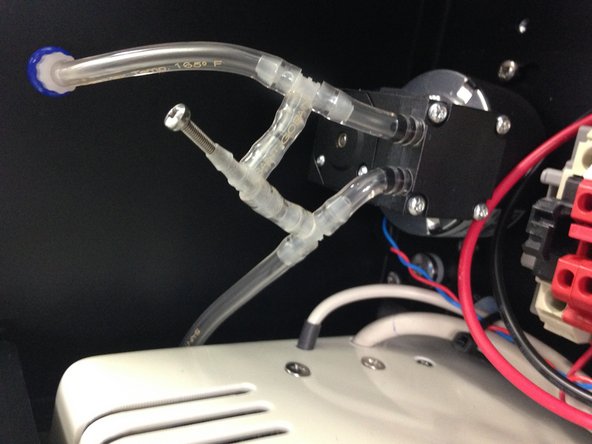

Open the monitor door and replace the gas inlet filer. Try to minimize the time the door is open so the sensors can quickly re-stabilize.

-

Measure and record the flow rate again.

-

If the inlet rate has changed from the previously recorded rate by less than ± 20 %, check the gas connections for obvious leaks, then use the flow adjustment valve to correct the flow. If the adjustment is unsuccessful, go to table 6 in the calibration form.

-

If the inlet flow has changed from the previously recorded rate by more than ± 20 %, go to table 6.

-

-

-

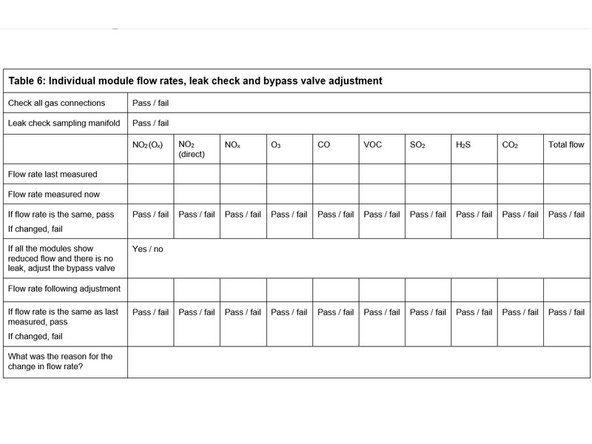

You only need to complete table 6 if the inlet flow rate was more than ± 20 % of the previously measured rate, or if using the flow adjustment valve to correct the inlet flow didn't work.

-

One or more modules can fail the flow check, but others can pass. Calibration can continue on modules that pass.

-

Modules that fail can be removed and checked without affecting the calibration on the remaining modules.

-

-

-

Check the individual gas connections for obvious leaks. If a leak is found, correct it.

-

Perform a leak check on the sampling manifold. If a leak is found, correct it.

-

-

-

It's important to have a high-quality flowmeter such as the TSI 4040 or the Bios Defender DryCal.

-

Record the individual flow rates the last time they were measured.

-

Measure and record today’s individual flow rates. Record the total flow.

-

For each module, if the flow rate now equals the previously measured flow rate (± 20 % LPM), pass that module. Otherwise fail it.

-

If no specific module is causing a problem and all module flow rates are low, adjust the flow rate using the bypass valve.

-

-

-

If no specific module is causing a problem and all module flow rates are low, adjust the flow rate using the bypass valve.

-

Re-measure and record flow rates for each module.

-

If the flow rate now equals the previously measured flow rate, pass it.

-

-

-

For those modules which don’t have the correct flow rate and can’t be corrected with the bypass valve, perform a leak check or check for blockages.

-

If the problem can’t be corrected, remove the module and cap off the gas connections. Record fail in the form.

-

The total flow rate is reduced when a module is removed.

-

If the door is left open for the purpose of finding a leak or removing a module, the gas modules will become unstable and you'll need to wait 1 – 2 hours to allow the sensors to re-stabilize.

-

For further support, contact Technical Support.

For further support, contact Technical Support.

Cancel: I did not complete this guide.

2 other people completed this guide.