Introduction

Commissioning is the process of setting up a new monitor to work correctly on site. It’s important that the correct procedure for commissioning the monitors is followed to ensure reliable monitor operation and to meet or exceed your data quality objectives.

All monitors are supplied with a traceable factory calibration. This calibration is applicable to the commissioning phase and accordingly Aeroqual does not recommend an initial calibration as part of monitor commissioning.

-

-

Carefully unpack the monitor, saving all the packaging and screws (you will need them again to repack the monitor if you plan to move it).

-

Check the monitor for damage.

-

-

-

-

-

-

Open the door and check that all tubing, power and data connections are secure.

-

-

-

Connect the power supply and switch on your monitor.

-

Check the status LED lights on the modules, embedded PC and modem (if fitted) turn green.

-

Check the fan at the rear of the monitor is working.

-

Check the compressor is running.

-

-

-

Connect to the monitor via Aeroqual Connect or Aeroqual Cloud.

-

-

Add a note in the journal that you are onsite for monitor commissioning.

-

-

-

Check the sampling system for leaks.

-

Rectify any leaks.

-

-

-

-

-

Check flow of gas inlet and adjust if required.

-

Check and adjust gas module flow rates to specification.

-

Check PM inlet flow rates and adjust if required.

-

-

-

Install calibration gas cylinders and regulators.

-

Configure your calibration schedule.

-

-

-

If you've purchased a third-party sensor (weather, noise), mount it, run the cabling through the external glands, and connect it to your monitor.

-

The type of sensor and age of the monitor dictate whether you connect the sensor using virtual AUX or by wiring it to the AUX module.

-

-

-

Close the door and wait for the internal temperature (Itemp) to stabilise.

-

This may take up to 4 hours, depending on ambient temperature.

-

Check the Itemp stabilises at the set point.

-

-

-

Once the internal temperature has stabilised, check the monitor has uploaded data continuously to Aeroqual Cloud.

-

Check the readings have stabilised to ambient conditions. There should be no negative values or missing data.

-

Check there are no failed or offline sensors in the journal.

-

-

-

Ensure the flow rates you measured previously haven't changed by more than 20%.

-

If they have, adjust the flow to be within the specifications detailed here: xxxxx

-

-

-

Turn on negative filters to exclude negative values from your dataset.

-

-

-

Add a note in the journal that the commissioning is complete. Record the commissioning tasks and the monitor's settings and readings.

-

-

-

-

If you are a distributor of Aeroqual monitors, you can also record the readings and settings of the monitor in a commissioning report.

-

Give the completed report to the customer, along with the monitor's factory logbook, to demonstrate correct commissioning.

-

The report form is attached to the bottom of this guide.

-

-

-

During the first month after installation, make sure:

-

All parameters are responding or ambient air

-

No parameters are flat lining

-

The power supply is stable

-

The communications are stable

-

The internal temperature (Itemp) is stable at the set point.

-

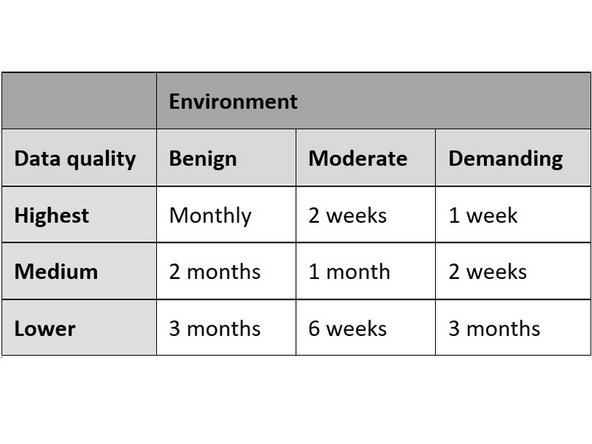

If the measurements don't meet your data quality goals, a calibration may be needed. Aeroqual can help you determine if you need to perform a calibration and can guide you through the process. Based on the data from the first month, you can plan your ongoing calibration schedule. Use this table to guide you.

-

For further support, contact Technical Support.

For further support, contact Technical Support.

Cancel: I did not complete this guide.

4 other people completed this guide.