Introduction

RGR CALKIT can be used to calibrate all Aeroqual sensor heads except ammonia, perchloroethylene, ozone and dust.

Gas calibration using the RGR CALKIT should always be completed in a location with adequate ventilation.

Parts

-

-

The calibration accessory has barbed fittings that are intended to fit with 1/8” ID tubing.

-

Care should be taken in selecting a tubing material that is appropriate for the type of gas that you will be using to calibrate the sensor head.

-

PVDF tubing is appropriate for most gases but the tubing's datasheet should be consulted for a full list.

-

Either side of the calibration accessory can be designated the inlet or the outlet.

-

Not all gas that enters through the inlet exits through the calibration accessory outlet; be advised that some gas exits through the sensor head exhaust. Depending on your calibration gas of choice and concentration levels, you may need to perform this calibration under a fume hood.

-

-

-

Make sure the valve on your flow gas regulator is fully off.

-

Screw the gas regulator onto your gas cylinder. When the regulator is correctly fitted, the pressure indicator will show the cylinder pressure.

-

Always point the cylinder and regulator away from yourself and others when attaching or removing a pressure regulator.

-

Secure the cylinder so it can't be knocked over while the regulator is attached.

-

-

-

Connect tubing to gas source and ventilation.

-

Either side of the calibration accessory can be designated the inlet or the outlet

-

-

Step 4 Attach the calibration accessory to the sensor head while the head is plugged into the Ranger

-

Attach the sensor head to Ranger

-

Turn Ranger On

-

Attach the calibration accessory to the sensor head

-

-

-

Check the cylinder pressure to ensure there's enough gas to perform the calibration (10% of full pressure should be enough).

-

Gently turn the regulator valve anticlockwise and flow the target gas at >1L/min until the reading stabilizes (about 10 minutes).

-

-

-

Wait for the gas reading to stabilize on the display of the Ranger

-

-

-

Press and hold the LEFT arrow key to enter the Settings menu

-

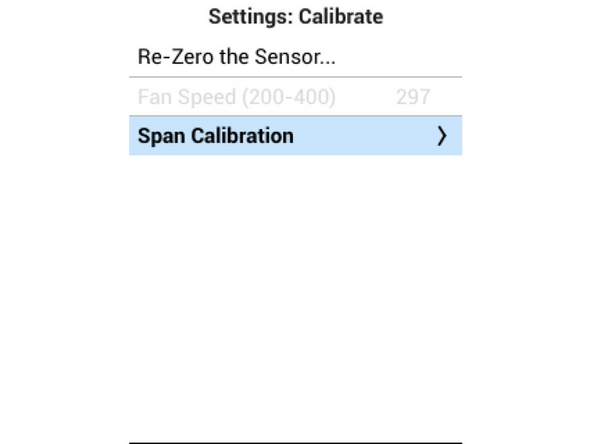

Navigate down and selectm 'Calibrate' and then ‘Span Calibration’

-

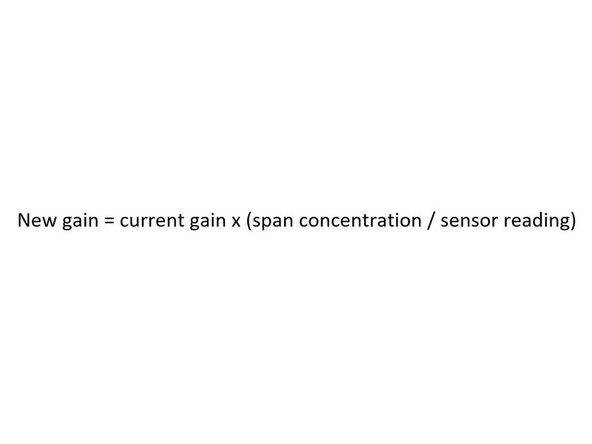

Enter the span adjustment menu and calculate the required gain using the formula

-

-

-

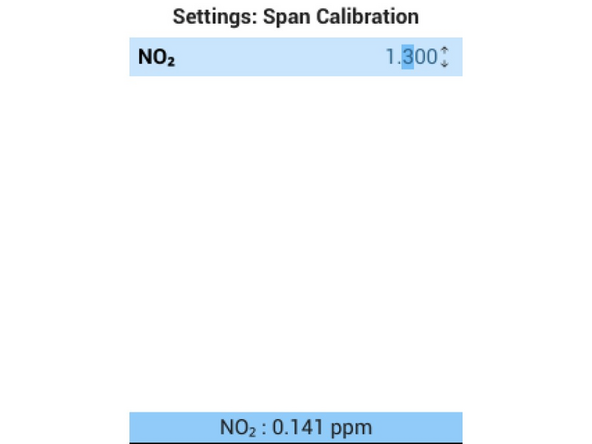

Adjust the gain value in the Span Calibration menu to match your calculated value

-

Press enter

-

Wait for the next sensor reading, which will have the new gain applied

-

The value is not applied until you press enter

-

The new gain value will be applied on the next measurement cycle; the value displayed at the bottom may take 1-2 minutes to update

-

Confirm the new reading matches your expected value.

-

Exit the span calibration menu.

-

-

-

Turn off the gas regulator.

-

Pack up.

-

-

-

If you remove the gas sensor head from any Ranger base, and attach it to a different Ranger base, the Span will be retained

-

For further support, visit Span calibration, How to test your sensor head , Sensors - VOC, or contact Technical Support.

For further support, visit Span calibration, How to test your sensor head , Sensors - VOC, or contact Technical Support.

Cancel: I did not complete this guide.

One other person completed this guide.