Introduction

A leak can be caused by loose connections, worn seals (o-rings) or split tubing.

If a leak occurs, this can affect the flow rate which will have a big impact on the accuracy of the measurement.

To understand how often you should perform this service activity, click here.

Tools

No tools specified.

Parts

-

-

Enter service mode so any fluctuations in the data caused from this activity can be excluded from air quality reports.

-

-

-

Adjust the sample flow by pulling the adjustment knob outwards, turning the knob to increase/decrease flow, and pushing the knob back in to lock when desired flow has been reached.

-

Fully open the sample flow adjustment valve, which is located on the face plate of the pump module.

-

On older monitors, the sample flow adjustment valve is positioned at the bottom of the enclosure under the PDI cover.

-

Block the purge flow by pinching the purge tube.

-

On older monitors, fully close the purge valve by pushing the valve handle towards the pump module.

-

-

-

Remove the TSP head and install the vacuum gauge above the sharp cut cyclone.

-

Wait for the gauge to stabilise.

-

The gauge should reach at least -60 kPa while power is connected.

-

-

-

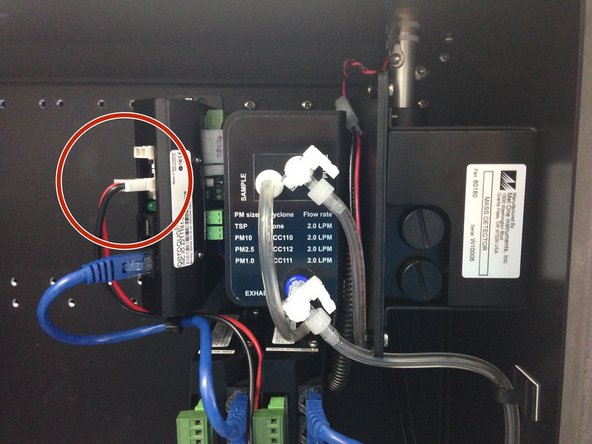

Stop the the sample and purge pumps by pulling out the black and red power cables from the electronics module.

-

Count how long it takes for the pressure to change by 10 kPa.

-

If the pressure change (leak rate) is greater than 10 kPa in 10 seconds, you'll need to check for loose connections, worn seals (o-rings) or split tubing.

-

For example, if the needle moves from -70 kPa to -60 kPa in 20 seconds, this is OK, but if if moves from -70 kPa to -60 Kpa in 8 seconds, this indicates a leak.

-

For further support, contact Technical Support.

For further support, contact Technical Support.

Cancel: I did not complete this guide.

2 other people completed this guide.