Introduction

Over time some particulate is inevitably deposited on the optics inside the optical engine. These deposits cause some scattering of light and result in a false positive reading, even in the absence of particle matter in the sample air. To limit this “drift” in the reading, the particle monitor executes an automatic auto zero cycle every 24 hours. The purpose of a zero cycle is to set a new baseline in absence of any particulate matter.

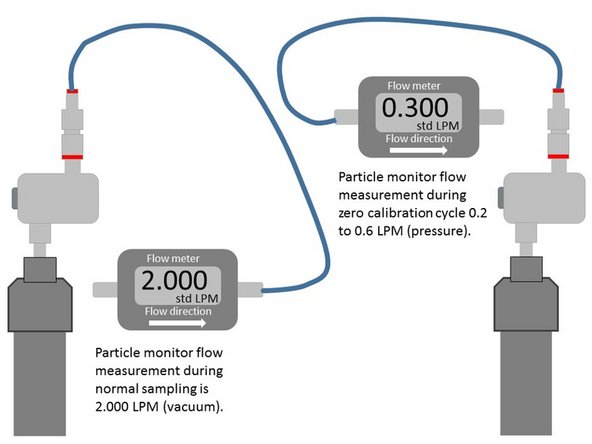

The zero cycle works by switching off the sample pump and switching on a purge (zero) pump. The flow rate during the zero cycle is reversed and is a positive flow out the particle inlet. The flow rate is approximately 0.2 to 0.6 LPM.

Particle matter concentrations during the zero cycle should read 0 or close to 0 (within the range ±3 µg/m3). If you’re seeing negative numbers larger than -3 µg/m3 in your data, it’s likely the auto zero cycle isn’t working correctly.

Note: The particle profiler doesn’t have an auto zero cycle.

To understand how often you should perform this service activity, click here.

Tools

No tools specified.

Parts

-

-

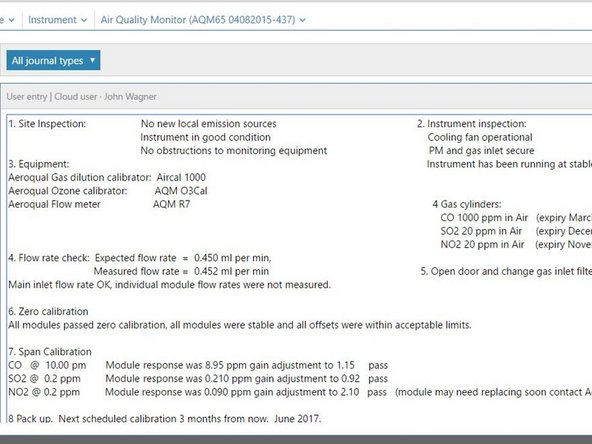

Enter service mode so any fluctuations in the data caused from this activity can be excluded from air quality reports.

-

-

-

Make sure the external zero filter isn’t on your sharp cut cyclone.

-

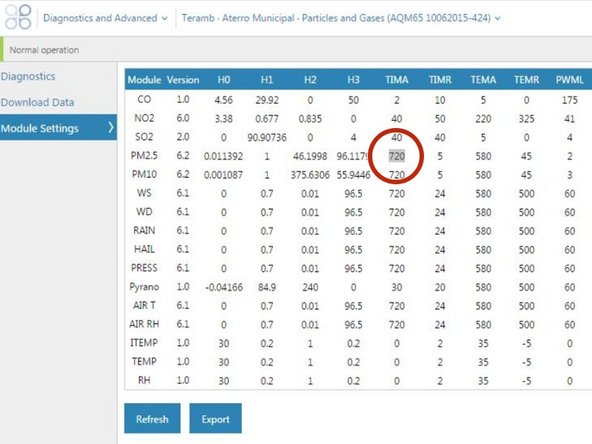

To manually start the auto zero cycle, enter the Diagnostic and Advanced app and select Module Settings from the side menu.

-

Find the TIMA parameter for your particle monitor (it should be 720).

-

Change this value to 1 by clicking in the cell and typing 1.

-

Save the setting change.

-

You'll hear a change in sound coming from the monitor.

-

The auto zero cycle takes about 6 minutes to complete.

-

-

-

During the auto zero cycle, attach a 0-2.5 LPM volumetric flowmeter to your monitor’s sharp cut cyclone.

-

If using a rotameter, connect the flow assembly tube to the bottom port of the flowmeter.

-

Measure the positive flow coming out of the inlet.

-

You should see a 0.2 to 0.6 positive flow. It doesn't need to be a specific value, but it must be at least 0.2. If no flow is measured, there may be an issue with the zero cycle or purge pump.

-

-

-

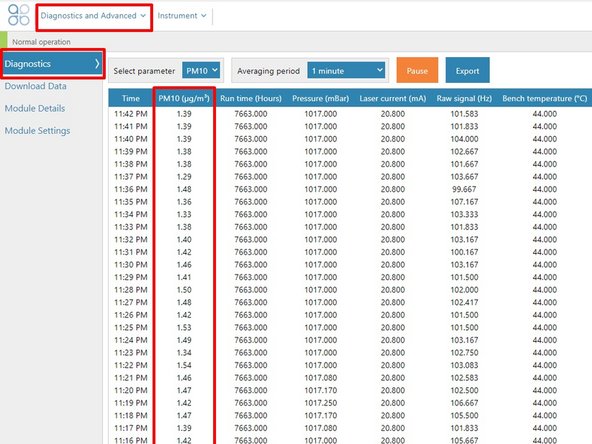

To view particle concentrations, open the Diagnostics and Advanced app and select Diagnostics from the side menu.

-

During the auto zero cycle, the Inlet column reads Zero and the PM µg/m3 values should be 0 or close to 0 (between ±3 µg/m3).

-

Compare the values with those taken during the zero filter check. They should be the same or very similar. If they're different, it’s possible the sample filter is too dirty or there's a problem with the auto zero cycle.

-

Return to Module Settings and reset the TIMA parameter from 1 to 720.

-

For further support, contact Technical Support.

For further support, contact Technical Support.