Introduction

Under some circumstances, sensors may temporarily exhibit a baseline reading higher than zero due to insufficient warm-up, or cross-sensitivity to other gases. In this case it is worthwhile checking against a standard zero air source.

Zero calibration involves delivering a certified clean air (sometimes called zero air) source to the sensor head and monitoring the response. If a non-zero reading is given, an adjustment is made so that the monitor reports zero concentration.

This guide will walk you through the steps to zero calibrate Type 1 sensor heads using a Series 500, 300, 200 or Ranger handheld monitor.

-

-

Set up the calibration accessory. Click here for AS R42. Click here for RGR CALKIT.

-

Make sure the sensor has warmed up for at least 30 minutes before performing a zero calibration.

-

-

-

Check the tubing type is Tygon.

-

Check the cylinger pressure to ensure there is enough zero air to perform the calibration (10% of full pressure should be enough).

-

Gently turn the regulator valve anticlockwise and flow the zero air until the reading stabilizes (about 10 minutes).

-

-

-

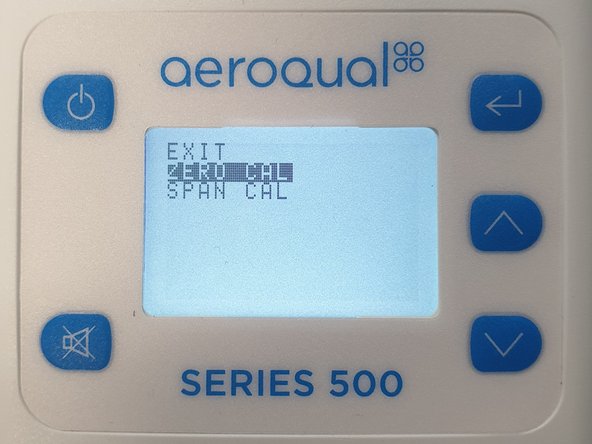

If you have a Series 200, 300 or 500 handheld monitor, follow these steps: Perform zero calibration

-

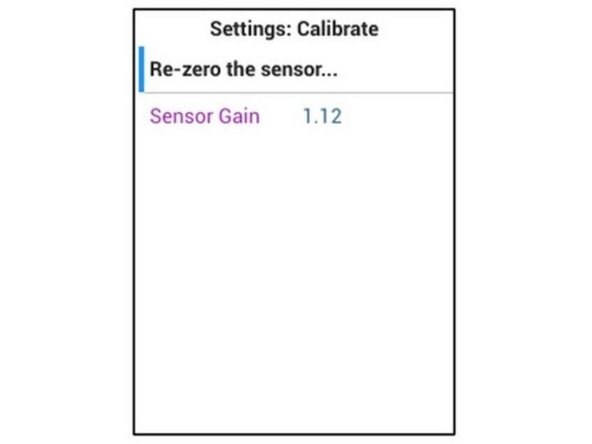

If you have a Ranger handheld monitor, follow these steps: Calibration - Gas zero

-

-

-

For extra help, watch our video.

-

For further support, contact Technical Support.

For further support, contact Technical Support.

Cancel: I did not complete this guide.

3 other people completed this guide.