Introduction

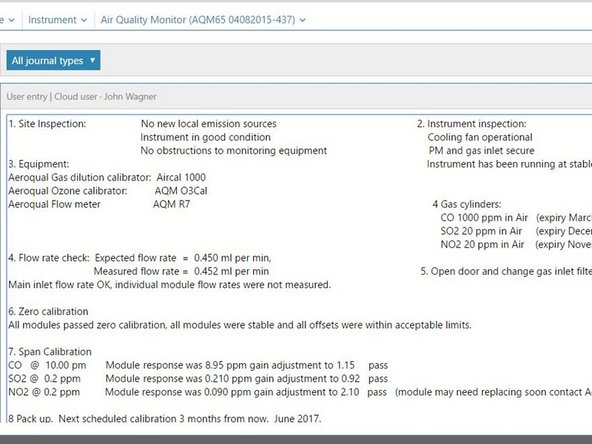

If all of your monitor’s gas modules show reduced flow, it’s likely the gas flow pump is aging. In this situation, you can adjust the flow bypass valve to provide more flow to the module inlets, and return the flow to the expected rate.

If you can't achieve the correct flow rate by adjusting the bypass valve, you may have to replace the gas sample pump.

To understand how often you should perform this service activity, click here.

Tools

Parts

-

-

Enter service mode so any fluctuations in the data caused from this activity can be excluded from air quality reports.

-

-

-

Attach a flowmeter to the gas inlet and measure the inlet flow.

-

Adjust the pump flow bypass valve until the gas inlet flow rate returns to the expected rate.

-

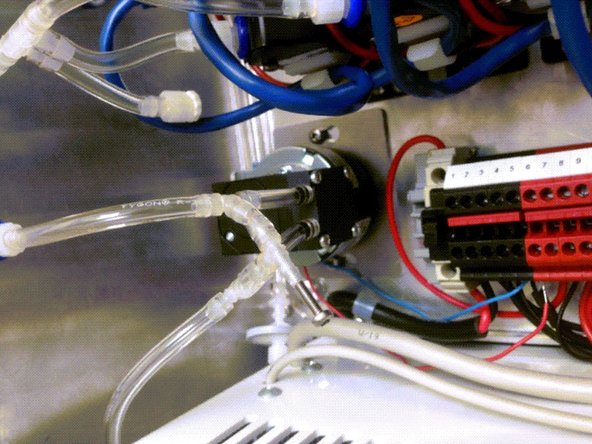

The bypass valve controls the flow rate by diverting a portion of the flow.

-

-

-

If you can't achieve the correct flow rate by adjusting the bypass valve, you may have to replace the sampling pump.

-

Disconnect the pump from the monitor's power system.

-

Unscrew the pump from the bracket.

-

Slide the two connectors out of the Tygon tubing.

-

Cut fresh lengths of Tygon tubing to connect the new pump to the main exhaust tubing.

-

This is important because the barbs on the old pump stretch the tubing when it's removed.

-

Screw the new pump to the bracket and attach it to the monitor's power system.

-

For further support, contact Technical Support.

For further support, contact Technical Support.

Cancel: I did not complete this guide.

One other person completed this guide.